Electrical Works

Electrical Works

Scope of Work:

The electrical works encompass the installation and commissioning of power and control cabling systems, including the preparation of cable routes, installation of Duck Banks, cable pulling, and termination as per project specifications and standards.

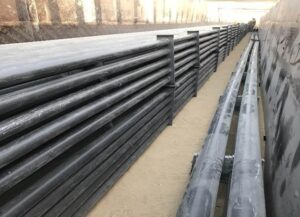

- Duck Bank Installation

- Definition: Duck Banks are pre-cast or constructed cable troughs or enclosures used to route and protect multiple power or control cables across areas such as roads, open fields, or equipment yards.

- Work Description:

- Site survey to determine the cable route and proper Duck Bank location.

- Excavation or foundation preparation for Duck Bank placement.

- Installation of Duck Bank units, ensuring proper alignment, leveling, and anchoring.

- Application of protective coatings or sealing to prevent water ingress (if required).

- Backfilling and compaction around the Duck Bank to ensure structural stability.

- Standards: Installation carried out in accordance with IEC, NEC, or project-specific electrical standards.

- Cable Pulling

- Work Description:

- Preparation of cable reels and staging areas for safe handling.

- Installation of temporary supports, rollers, or sheaves along the cable route to minimize bending stress.

- Pulling of power and control cables through conduits, trays, Duck Banks, or direct buried paths using manual or mechanical methods.

- Monitoring pulling tension and velocity to prevent cable damage.

- Inspection of cable for mechanical damage, kinking, or insulation defects before and after installation.

- Safety Considerations:

- Adherence to safe working loads.

- Use of proper PPE and handling equipment.

- Coordination with site electrical isolation protocols.

- Cable Termination

- Work Description:

- Preparation of cable ends including stripping, cleaning, and conductor preparation.

- Installation of lugs, glands, ferrules, or terminations as per cable type (XLPE, PVC, armored, etc.).

- Crimping, soldering, or compression of cable lugs to ensure electrical and mechanical reliability.

- Insulation and stress relief applied using heat-shrink or cold-shrink materials.

- Connection to switchgear, panel boards, transformers, junction boxes, or other electrical equipment.

- Testing and verification of continuity, insulation resistance, and polarity.

- Standards: Compliant with IEC 60287, IEC 60502, NEC, and project-specific requirements.

- Quality Assurance & Testing

- Visual inspection for compliance with drawings and specifications.

- Insulation resistance testing using megger.

- Continuity and polarity verification.

- Documentation of cable schedules, test results, and as-built information